DTF Printing Revolution: Unleashing Creativity in Textile Design and Production

DTF Printing Revolution: Unleashing Creativity in Textile Design and Production

Blog Article

The Future of Fashion: Discovering DTF Printing Technology in the Fabric Industry

Among these improvements, Straight to Film (DTF) printing innovation has actually arised as an encouraging contender, providing distinct capabilities and possibilities for developers and makers alike. This cutting-edge printing method has sparked interest due to its potential to revolutionize conventional textile printing processes.

Evolution of Textile Printing

From the old human beings making use of methods like block printing to the digital change of today, textile printing has consistently pushed boundaries. As the craft spread to various other parts of the globe, new methods such as display printing and roller printing emerged throughout the Industrial Transformation, transforming the textile market.

The intro of digital textile printing in the late 20th century noted a substantial shift in the direction of even more functional and sustainable printing techniques. The advancement of textile printing showcases a rich history of creative thinking, ingenuity, and technological development in the globe of style and design.

Benefits of DTF Innovation

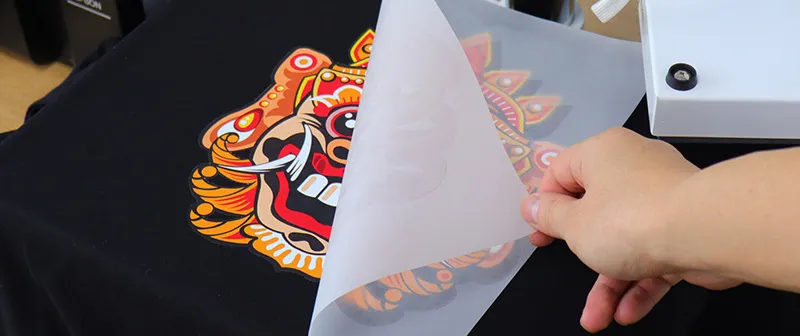

With the advancement of textile printing methods from old methods like block printing to modern advancements such as electronic printing, the intro of Direct-to-Fabric (DTF) modern technology has actually considerably improved the effectiveness and sustainability of fabric printing procedures. Among the key advantages of DTF technology is its ability to directly print designs onto fabric without the need for transfer papers, which lowers waste and streamlines the manufacturing procedure. In addition, DTF printing permits better shade vibrancy and information precision compared to conventional approaches, enabling fabric suppliers to create detailed and high-grade layouts with convenience.

Furthermore, DTF innovation is understood for its versatility, as it can be made use of on different kinds of textiles, consisting of all-natural fibers like cotton, wool, and silk, along with artificial products such as polyester and nylon (DTF Printing). This versatility opens up a vast array of opportunities for suppliers and developers to try out different appearances and products, resulting in even more ingenious and distinct products in the apparel industry. In general, the execution of DTF innovation represents a substantial innovation in textile printing, offering countless advantages that add to the future sustainability and imagination of the sector

Sustainability in vogue Manufacturing

Highlighting environment-friendly practices is vital in contemporary style production, lining up with the expanding consumer need for sustainable items. In recent times, the fashion business has actually faced raising scrutiny as a result of its significant ecological impact, consisting of excessive water use, chemical air pollution, and textile waste. As a response, lots of style brands are currently incorporating lasting methods right into their manufacturing processes to decrease damage to the setting.

Sustainability in vogue manufacturing encompasses different aspects, such as making use of recycled and organic materials, lowering energy intake, executing moral labor practices, and advertising transparency throughout the supply chain. Additionally, improvements in technology, like DTF printing, deal YOURURL.com opportunities to even more improve sustainability in fabric manufacturing. This modern technology enables exact printing on textiles, reducing ink waste and water use compared to conventional printing approaches.

Design Freedom and Personalization

Additionally, DTF printing helps with modification on a scale formerly unattainable, allowing for customized apparel and distinct items tailored to private choices. In general, DTF printing modern technology transforms the style landscape in the textile more market, supplying unlimited opportunities for creative expression and individualized style.

Influence On Supply Chain & Market Trends

DTF printing technology in the fabric sector is improving supply chain characteristics and affecting market fads via its efficiency and modification capacities. By enabling on-demand printing and eliminating the need for large inventories, DTF technology streamlines the supply chain process.

Moreover, the personalization potential of DTF printing innovation is changing the market patterns in the fabric industry. As a result, DTF modern technology is driving a shift in the direction of more innovative and customer-centric techniques within the fabric market, forming the future of fashion.

Conclusion

Finally, DTF printing technology is transforming the fabric industry by using numerous benefits such as style sustainability, modification, and freedom. This ingenious innovation is improving the future of fashion production, affecting supply chains, and driving market fads in the direction of more green and efficient practices. As the industry remains to develop, DTF printing will certainly play a vital duty fit the way textiles are generated and consumed in the years to find.

From the ancient civilizations making use of strategies like block printing to the electronic change of today, fabric printing has actually pop over to this site constantly pushed limits. As the craft spread to various other parts of the world, new approaches such as display printing and roller printing arised during the Industrial Transformation, revolutionizing the fabric sector.

The intro of digital textile printing in the late 20th century noted a substantial change towards more functional and sustainable printing methods.With the evolution of fabric printing methods from ancient methods like block printing to modern-day technologies such as digital printing, the introduction of Direct-to-Fabric (DTF) modern technology has actually considerably enhanced the performance and sustainability of fabric printing processes (DTF Printing).In feedback to the imperative change towards sustainability in style manufacturing, the adoption of cutting-edge innovations like DTF printing not only addresses environmental concerns yet likewise opens up methods for unmatched style liberty and personalization in the textile sector

Report this page